Pressed Coupler

“Trusted Solutions for Every Project”

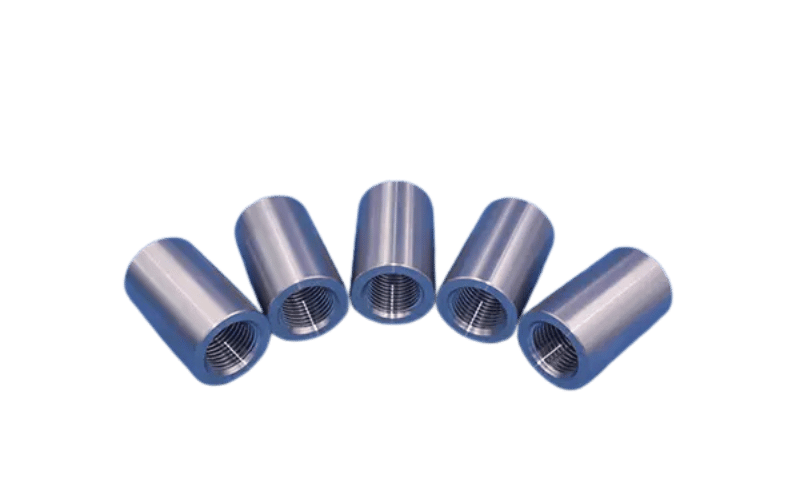

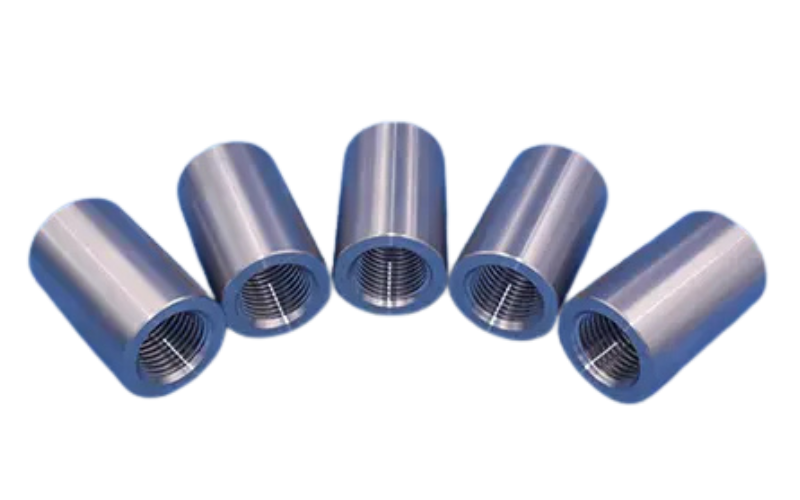

Pressed Coupler

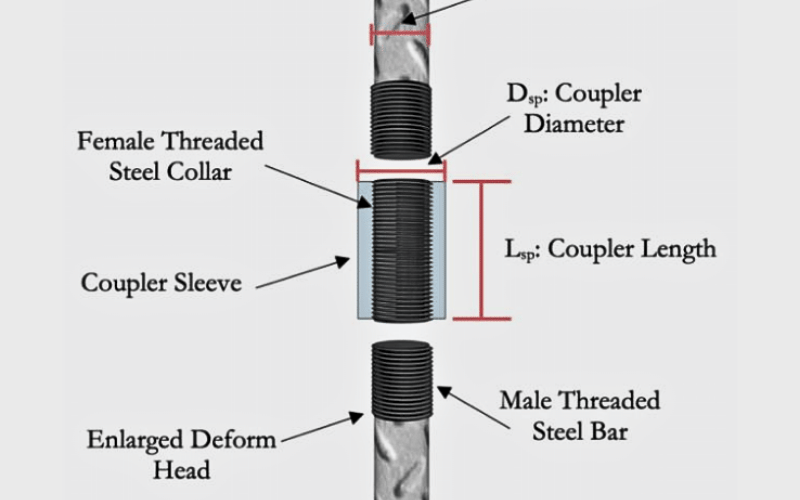

The Pressed Coupler is a cost-effective, fast, and highly reliable solution for joining reinforcement bars without the need for threading or welding. Using a hydraulic press, the coupler securely grips the inserted rebars, creating a full-strength, slip-free mechanical splice.

This system is particularly suitable for on-site applications where threading machines are not feasible, or in precast construction where speed and ease of installation are critical. With minimal preparation and robust performance, Bestnotch Pressed Couplers deliver efficiency, safety, and structural integrity across diverse construction projects.

Key Features

- No Threading Required – Eliminates the need for bar-end preparation.

- Quick Installation – Hydraulic pressing allows rapid connections on-site.

- Full-Strength Joint – Coupler strength equals or exceeds the rebar’s parent strength.

- Labor & Cost Savings – Simple operation reduces skilled labor requirements.

- Versatility – Can be used in vertical, horizontal, and congested reinforcement zones.

- Durability – Withstands seismic loads, dynamic stresses, and vibrations.

- Reliable Grip – Special internal profile ensures maximum contact with rebar surface.

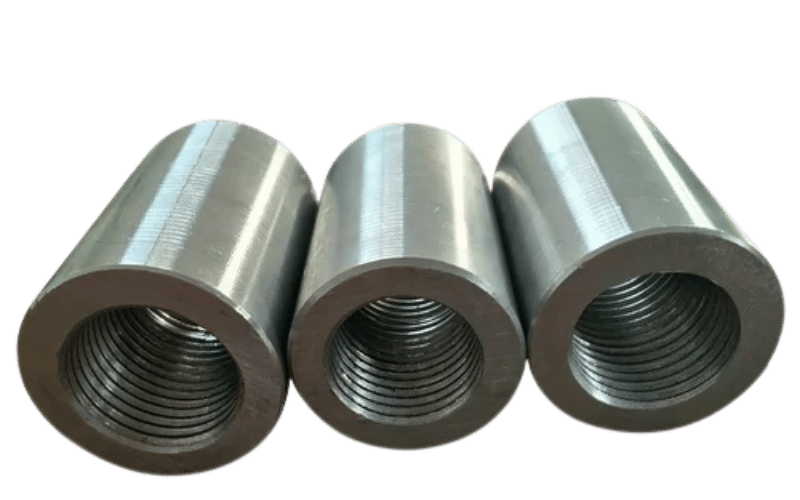

Technical Specifications

|

Parameter |

Details |

|

Coupler Material |

High-strength alloy steel |

|

Applicable Bar Grades |

Fe500 / Fe550 / ASTM A615 / BS4449 |

|

Bar Diameter Range |

12 mm – 40 mm (custom sizes available) |

|

Joint Strength |

≥ 100% of parent bar tensile strength |

|

Slip (under load) |

< 0.05 mm |

|

Surface Finish |

Black, zinc-coated, or epoxy finish |

|

Compliance |

BS8110, Eurocode 2, ACI 318, JGJ107, ISO 15835 |

Applications

- Precast construction (columns, beams, walls, panels)

- Raft foundations and pile caps

- Bridges, tunnels, and flyovers

- Constrained spaces where threading is difficult

- Temporary or fast-track construction projects

Advantages

- No need for threading machines or cold-forging equipment.

- Faster installation compared to threading or welding methods.

- Reduces project downtime due to easy on-site handling.

- Effective in situations with limited working space.

- Lower overall installation cost.

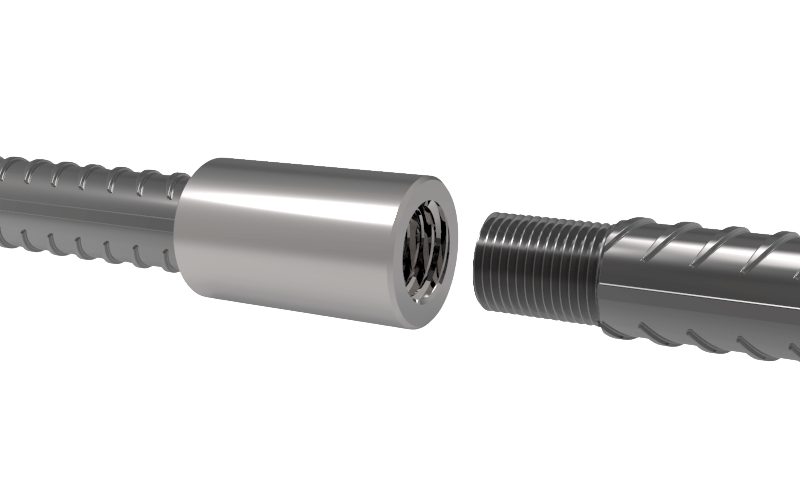

Installation Process

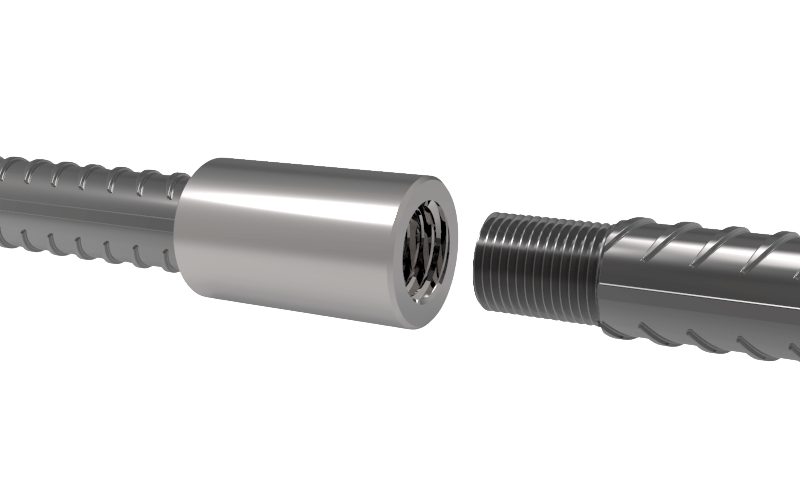

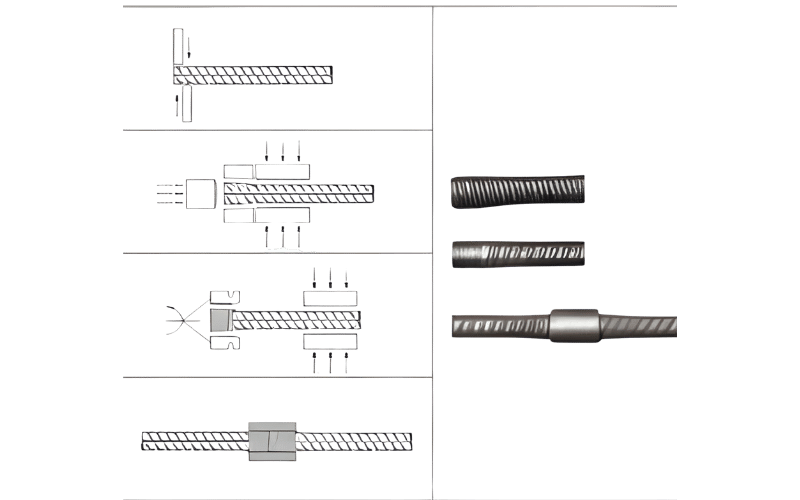

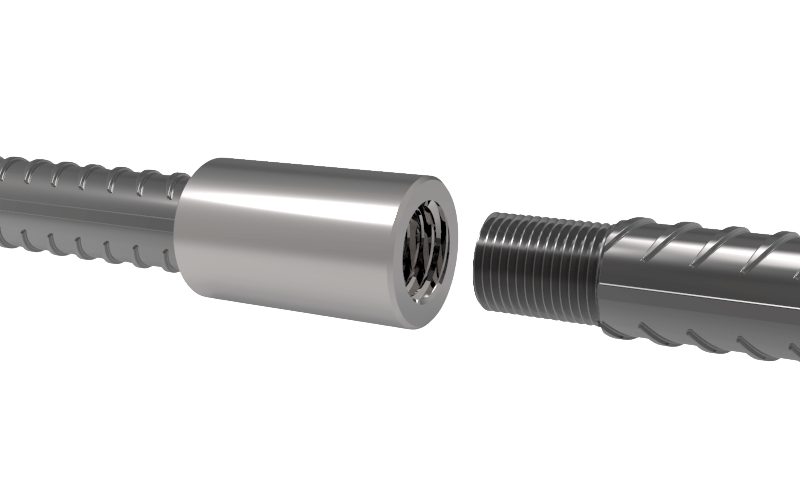

Step 1: Bar Insertion

- Cut and clean the rebar ends.

- Insert both rebars into the coupler until they meet at the center mark.

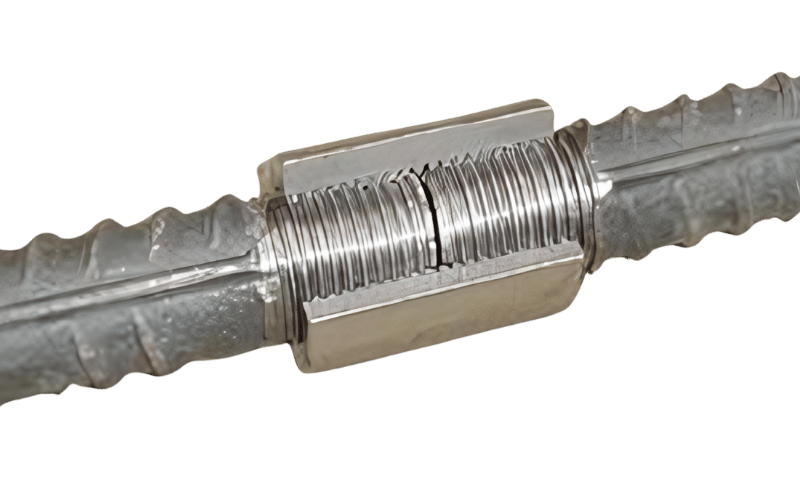

Step 2: Hydraulic Pressing

- Place the hydraulic press tool around the coupler.

- Apply the required pressure until the coupler jaws fully compress around the rebars.

- Pressing deforms the coupler walls, locking tightly onto the rebar surface.

Step 3: Final Check

- Ensure the coupler shows full, even pressing marks.

- Confirm that both rebars are firmly locked with no movement.

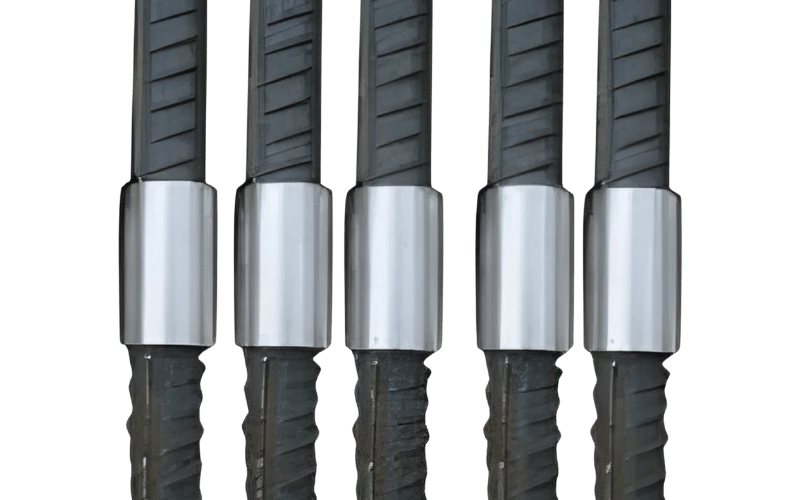

Variants Available

- Standard Pressed Coupler – For normal splicing applications.

- Positional Pressed Coupler – Used where one bar cannot be rotated or moved.

- Transition Pressed Coupler – Joins rebars of different diameters.

Quality & Testing

To guarantee consistent performance, every Pressed Coupler is tested for:

- Tensile load capacity

- Slip resistance

- Fatigue endurance

- Corrosion resistance (coating check)

- Dimensional accuracy

OUR PRODUCTS

Parallel Threaded Couplers

Pressed Coupler

Weldable Coupler

One-Touch Coupler

BEST NOTCH GROUP LLC.

Best Notch Group LLC, headquartered in Dubai, is a leading rebar coupler supplier in the UAE, specializing in high-quality and advanced connection systems for the construction industry. We manufacture and supply a wide range of couplers.