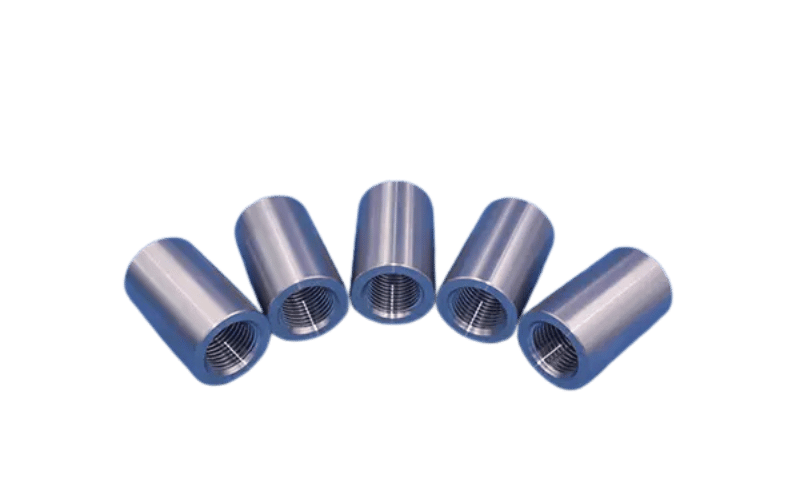

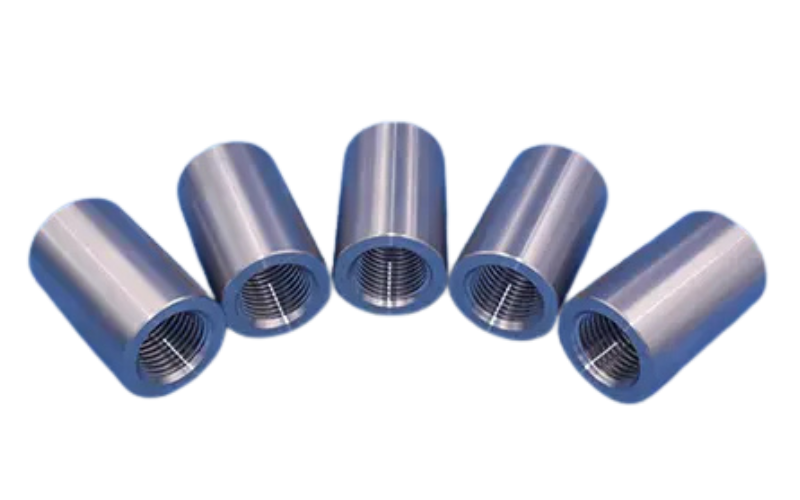

Parallel Threaded Couplers

“Engineered for Reliability, Built for Durability.”

Parallel Threaded Couplers

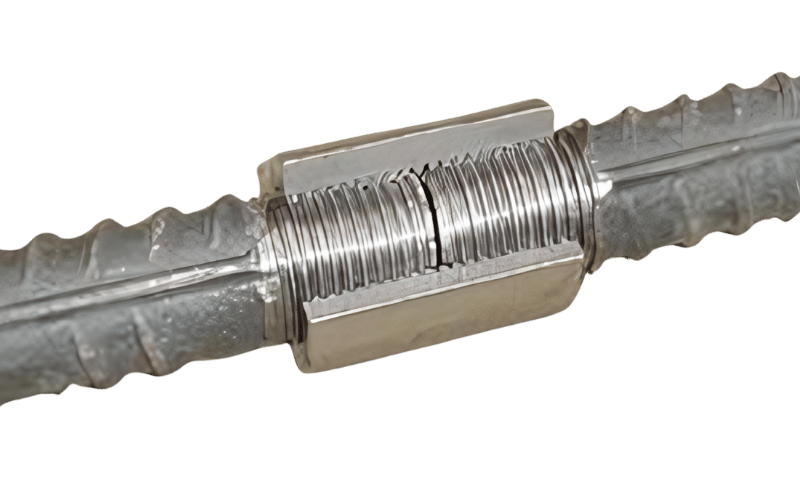

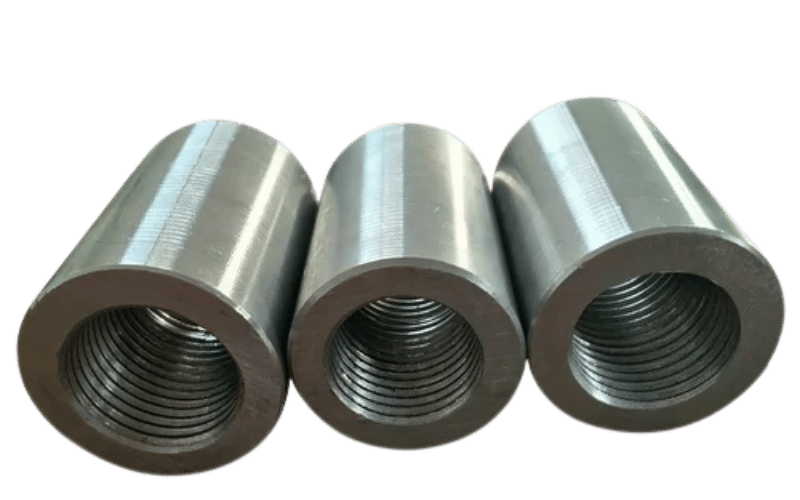

The Parallel Threading Coupler is one of the most reliable and widely used mechanical splicing solutions for reinforcement bars. It is designed to provide full-strength, permanent joints that meet or exceed the tensile strength of the parent rebar. Using a cold-forging and threading technique, the coupler ensures precision, durability, and performance in even the most demanding projects.

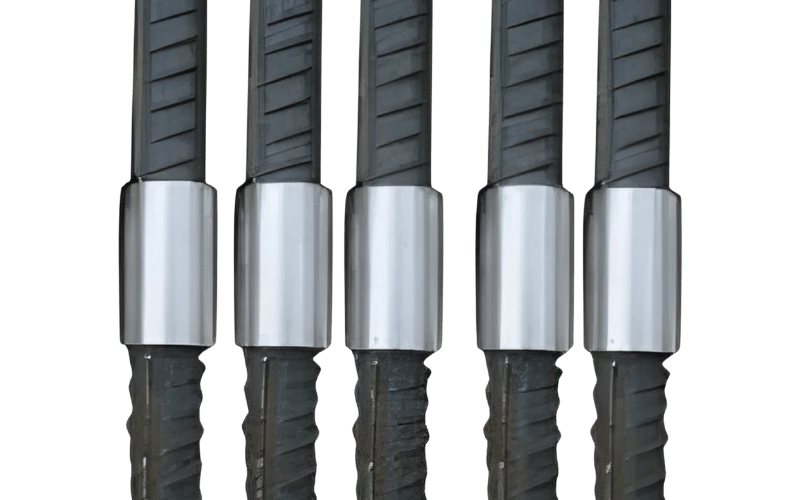

Whether for high-rise buildings, bridges, tunnels, or precast structures, Best Notch Parallel Threading Couplers deliver consistent quality and efficiency while reducing material wastage and congestion.

Key Features

- High Strength – Exceeds 125% of parent rebar yield strength (depending on grade).

- Compact Design – Ideal for areas with dense reinforcement where lapping is impractical.

- Versatility – Suitable for bar diameters ranging from 12 mm to 50 mm (custom sizes available).

- 360° Load Transfer – Ensures uniform stress distribution across the joint.

- Durability – Resistant to fatigue, vibration, and seismic loads.

- Code Compliance – Conforms to ACI 318, BS 8110, Eurocode 2, and JGJ107 standards.

Technical Specifications

|

Parameter |

Details |

|

Coupler Material |

High-grade carbon steel (heat-treated for strength) |

|

Thread Type |

ISO Metric, parallel thread |

|

Rebar Compatibility |

Fe500 / Fe550 / ASTM A615 / BS4449 / equivalent grades |

|

Bar Diameter Range |

12 mm – 50 mm (other diameters available on request) |

|

Tensile Strength |

≥ parent rebar strength |

|

Slip (under tension) |

< 0.05 mm |

|

Coating / Finish |

Black, zinc-plated, or epoxy-coated (project-specific) |

|

Compliance |

BS8110, ACI 318, Eurocode 2, JGJ107, ISO 15835 |

Applications

- High-rise towers and skyscrapers

- Bridges and flyovers

- Tunnels and underground works

- Precast concrete elements

- Foundations and raft slabs

- Seismic and high-load structures

Advantages

- Saves up to 30–40% steel compared to overlap methods.

- Reduces congestion in heavily reinforced areas.

- Shortens project schedules due to quicker assembly.

- Enables continuation of work without waiting for staggered lap lengths.

- Eco-friendly due to material efficiency and waste reduction.

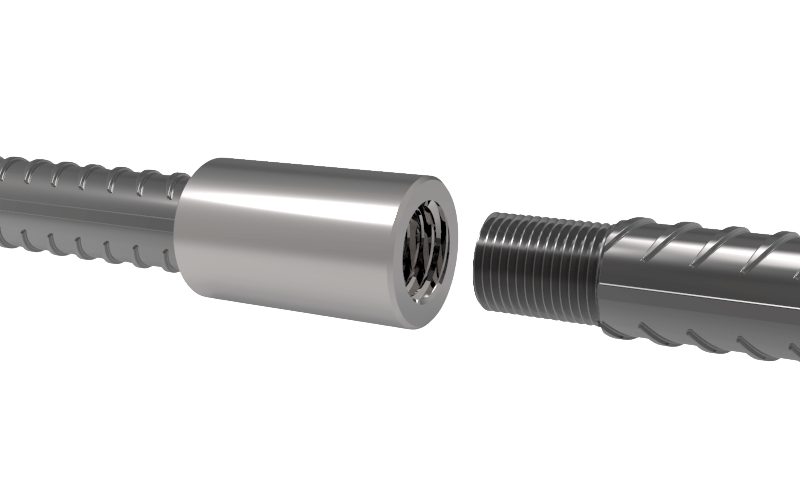

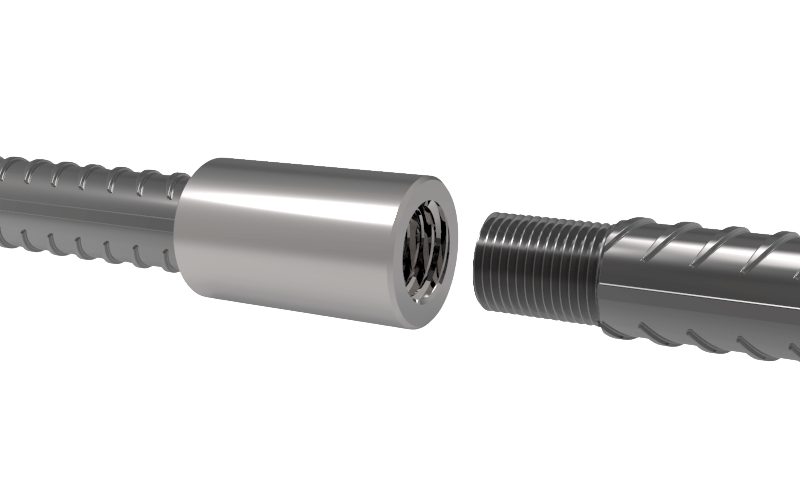

Installation Process

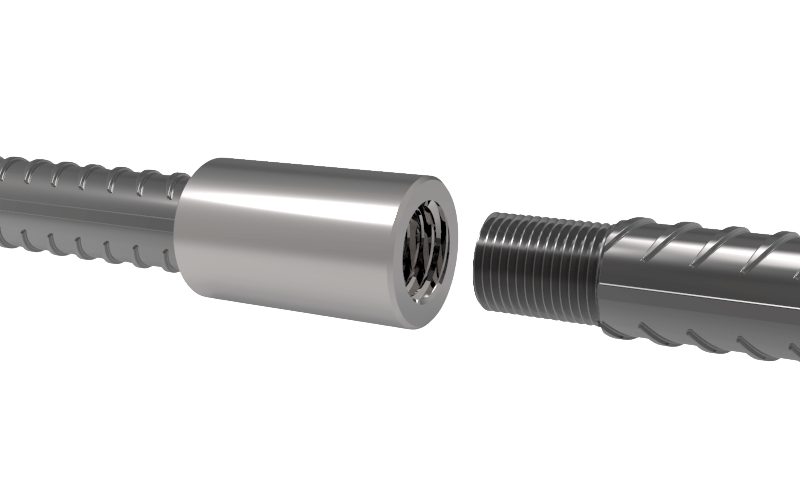

Step 1: Bar Preparation

- Rebar ends are cold-forged using a hydraulic press to increase diameter.

- Parallel threads are then cut onto the forged ends with a threading machine.

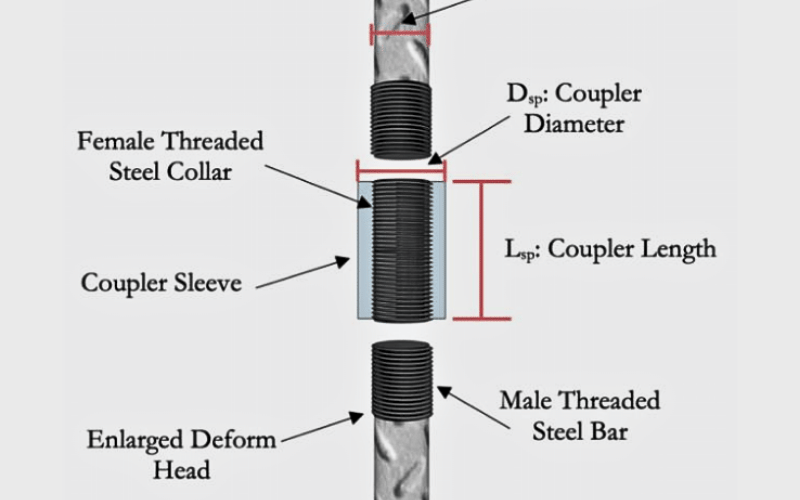

Step 2: Coupler Connection

- The first bar is screwed into the coupler until it reaches the internal stop.

- The second bar is aligned and threaded into the opposite side of the coupler.

Step 3: Final Check

- Ensure both bars are tightened to full depth (using a torque wrench if required).

- No gaps or visible threads should remain.

Optional: On-site inspections may be conducted to confirm tensile and slip compliance.

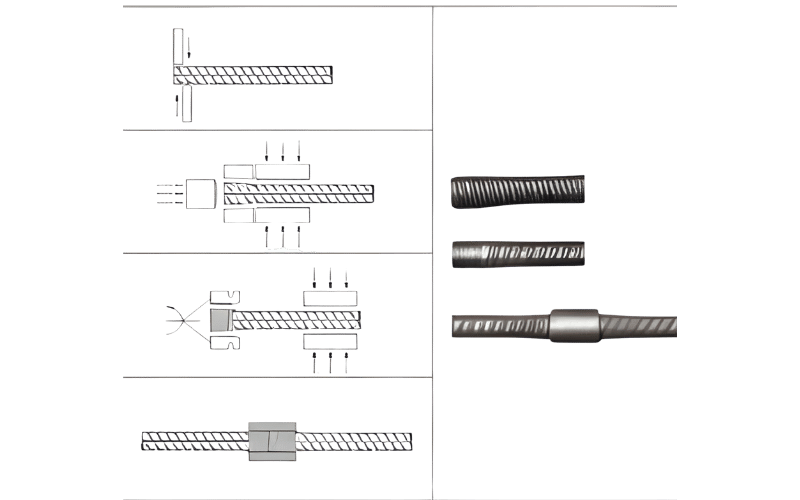

Variants Available

- Standard Parallel Thread Coupler – For normal applications where both bars can be rotated.

- Positional Coupler – When one bar cannot be rotated; coupler allows adjustment in position.

- Transition Coupler – For joining rebars of different diameters.

- Terminal Coupler – For rebar anchorage to structural steel plates.

Quality & Testing

Every batch of Best Notch Parallel Threading Couplers undergoes:

- Dimensional inspection

- Tensile strength test

- Slip test

- Fatigue test (for seismic and dynamic structures)

- Coating thickness and finish check

OUR PRODUCTS

Parallel Threaded Couplers

Pressed Coupler

Weldable Coupler

One-Touch Coupler

BEST NOTCH GROUP LLC.

Best Notch Group LLC, headquartered in Dubai, is a leading rebar coupler supplier in the UAE, specializing in high-quality and advanced connection systems for the construction industry. We manufacture and supply a wide range of couplers.