Bolted Coupler

“Setting Standards in Coupler Systems”

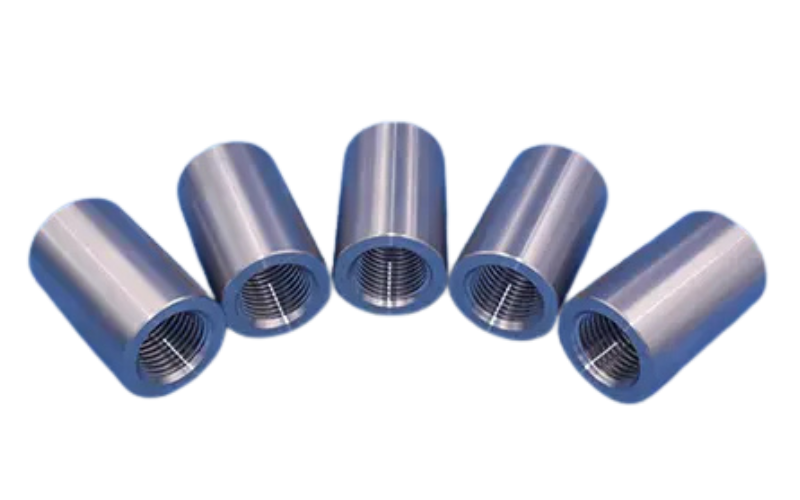

Bolted Coupler

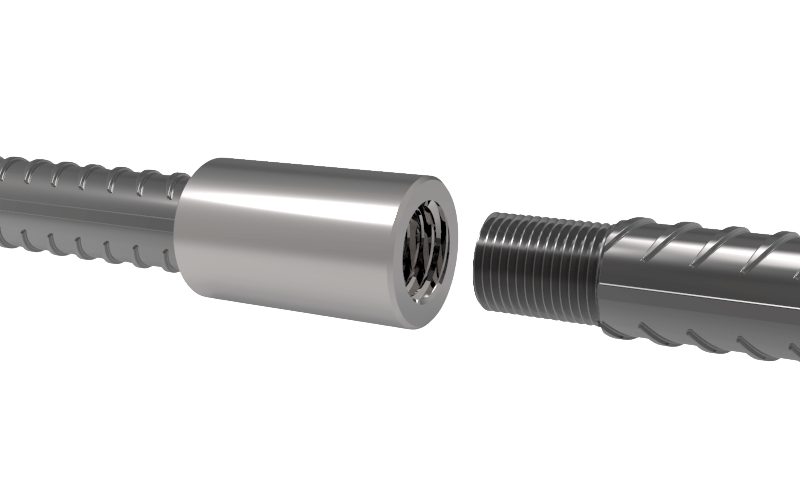

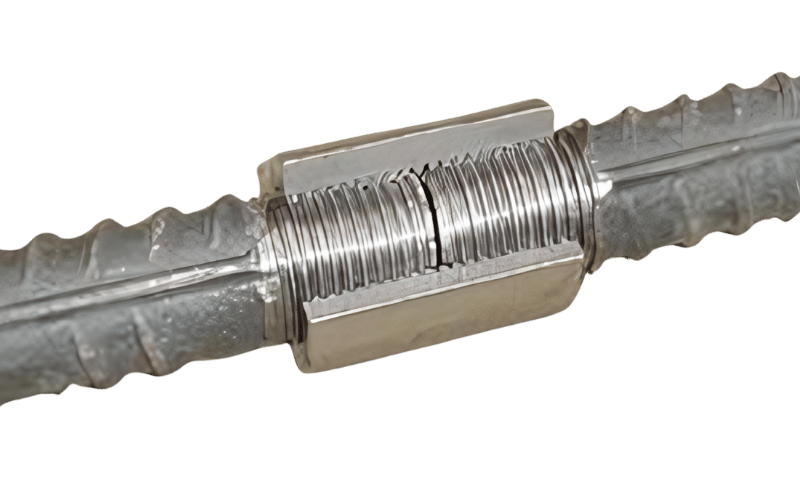

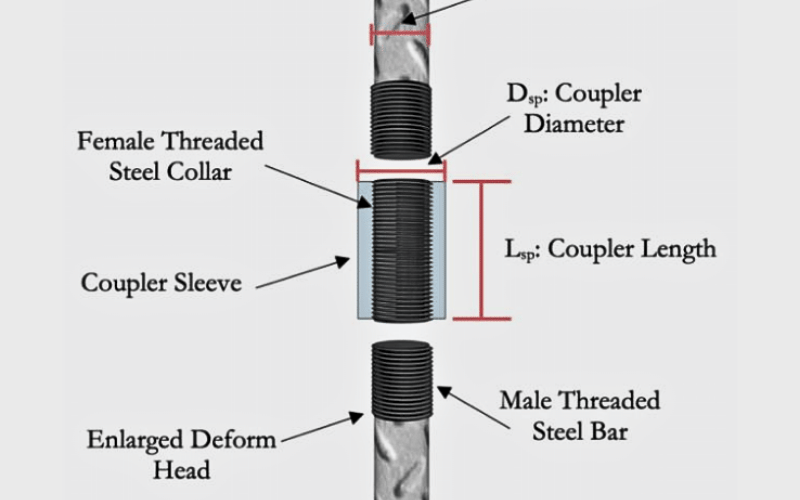

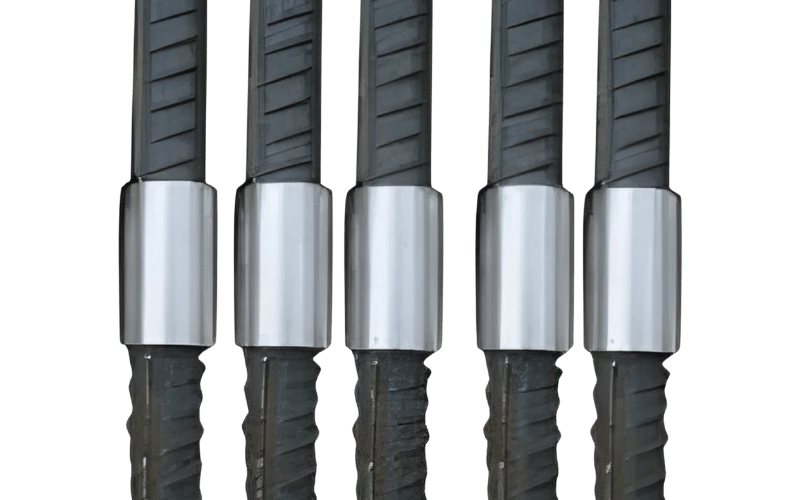

The Bolted Coupler is a simple, robust, and highly adaptable rebar splicing system that joins reinforcement bars using high-strength bolts. Unlike threaded or pressed systems, bolted couplers require no bar-end preparation, threading, or special machinery. They are especially useful in retrofit projects, emergency repairs, and locations with restricted access, where speed and reliability are critical.

By clamping directly onto the reinforcing bars, bolted couplers provide a secure, slip-resistant connection that meets structural strength requirements and ensures seamless load transfer.

Key Features

- No Bar-End Preparation – Simply cut the bar square and insert into coupler.

- Bolt Locking System – High-strength bolts tighten the connection securely.

- Quick Installation – Ideal for urgent splicing and repair works.

- Full Strength Joint – Equal to or greater than parent bar strength.

- Rebar Tolerance Flexibility – Can connect slightly misaligned or irregular bars.

- Minimal Equipment Required – Only a torque wrench needed for tightening bolts.

- Reusable & Practical – Suitable for temporary and permanent applications.

Technical Specifications

|

Parameter |

Details |

|

Coupler Material |

High-strength alloy steel |

|

Bolt Material |

Heat-treated, high-tensile steel |

|

Bar Diameter Range |

12 mm – 40 mm (larger sizes on request) |

|

Applicable Bar Grades |

Fe500 / Fe550 / ASTM A615 / BS4449 |

|

Joint Strength |

≥ 100% of parent bar tensile strength |

|

Slip (under tension) |

< 0.1 mm |

|

Corrosion Protection |

Zinc-coated or epoxy finish |

|

Compliance |

BS8110, Eurocode 2, ACI 318, JGJ107, ISO 15835 |

Applications

- Emergency or retrofit works (where threading/welding is not possible).

- Bridges, tunnels, and repair projects.

- Confined spaces with limited access to heavy machines.

- Temporary reinforcement connections.

- Sites where on-site threading or pressing tools are unavailable.

Advantages

- No specialized tools, threading, or hydraulic presses required.

- Easy to install in tight or restricted areas.

- Allows bar connection even with minor misalignments.

- Saves time in urgent situations (ideal for repairs or retrofits).

- Low skill requirement for installation.

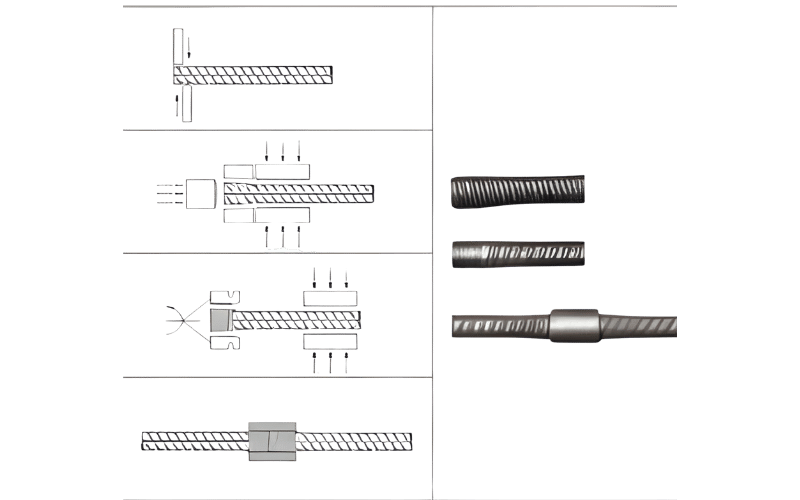

Installation Process

Step 1: Bar Preparation

- Cut the rebar ends square.

- Clean off rust, oil, or dirt for a firm grip.

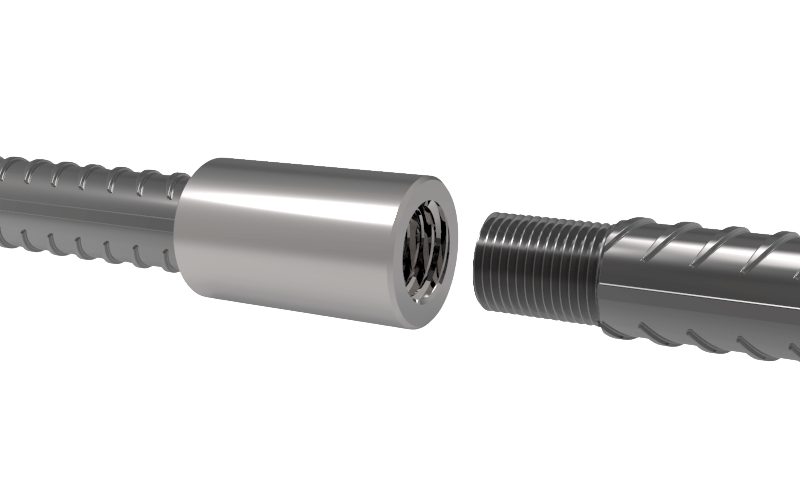

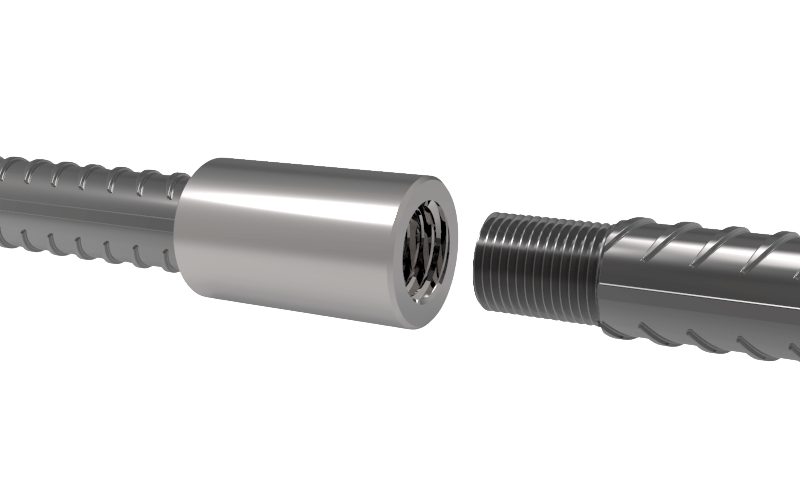

Step 2: Coupler Placement

- Insert both rebar ends into the coupler until they meet at the center stop.

Step 3: Bolt Tightening

- Tighten the bolts alternately using a torque wrench.

- Ensure each bolt is tightened to the recommended torque.

- The bolts embed into the bar surface, locking the connection securely.

Step 4: Final Check

- Inspect that all bolts are fully tightened and evenly secured.

- Ensure no visible gaps remain between bar ends and coupler interior.

Variants Available

- Standard Bolted Coupler – For typical reinforcement splicing.

- Positional Bolted Coupler – Allows bar connection without rotation.

- Transition Bolted Coupler – Joins different diameter rebars.

- Emergency Bolted Coupler – Specially designed for urgent retrofitting works.

Quality & Testing

Each Best Notch Bolted Coupler undergoes strict quality control:

- Tensile & slip resistance testing

- Torque testing for bolt tightening strength

- Fatigue resistance under cyclic loads

- Coating durability & corrosion protection tests

OUR PRODUCTS

Parallel Threaded Couplers

Pressed Coupler

Weldable Coupler

One-Touch Coupler

BEST NOTCH GROUP LLC.

Best Notch Group LLC, headquartered in Dubai, is a leading rebar coupler supplier in the UAE, specializing in high-quality and advanced connection systems for the construction industry. We manufacture and supply a wide range of couplers.