Revolutionizing Rebar Connections

Effortless Strength with Bestnotch Couplers

Discover the advanced technology behind our rebar parallel thread couplers, designed to enhance structural integrity and streamline construction processes.

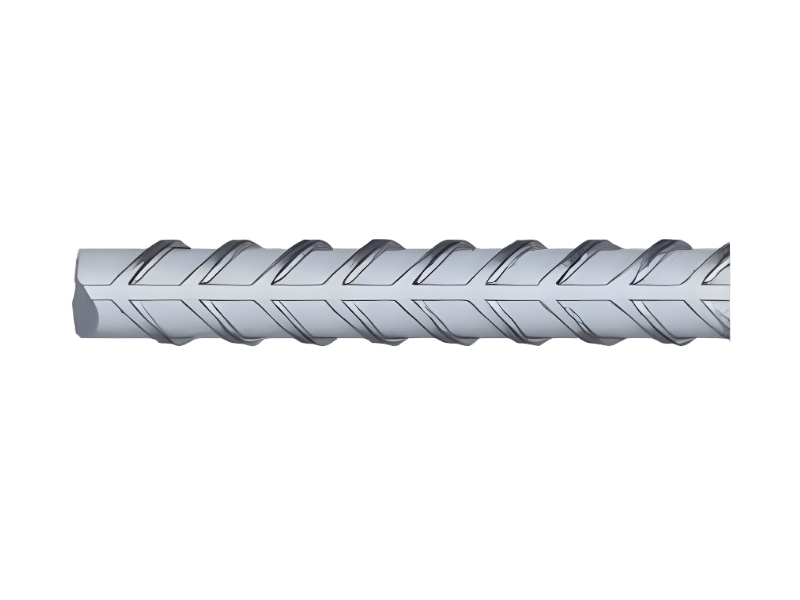

Introducing Best Notch Rebar Couplers

Unmatched Engineering for Superior Structural Performance

1

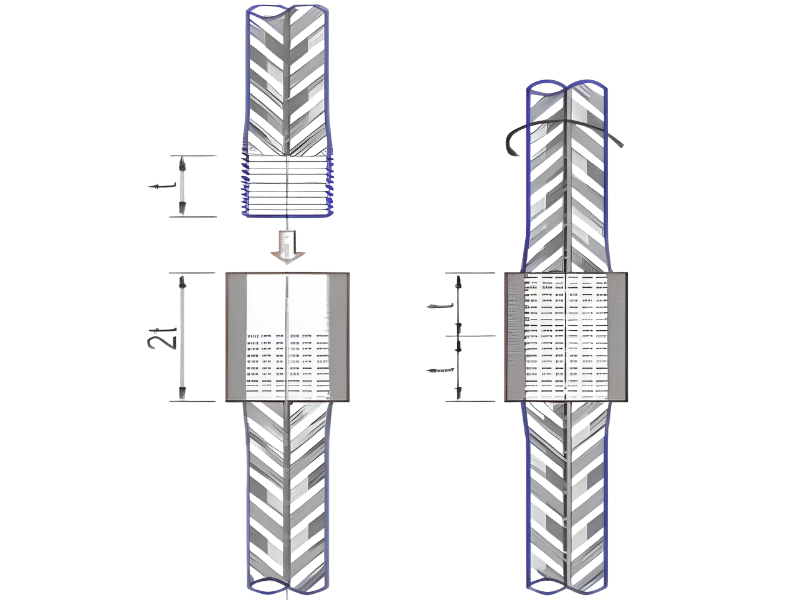

Step A: Precision Rebar Cutting

2

Step B: Cold Upsetting Process

3

Step C: Thread Cutting Precision

Step A: Cutting the Rebar End

Flat‑cut rebar end prepared for forging. Description: The rebar end is cut square to ensure proper alignment and optimal material flow during the cold‑upsetting process.

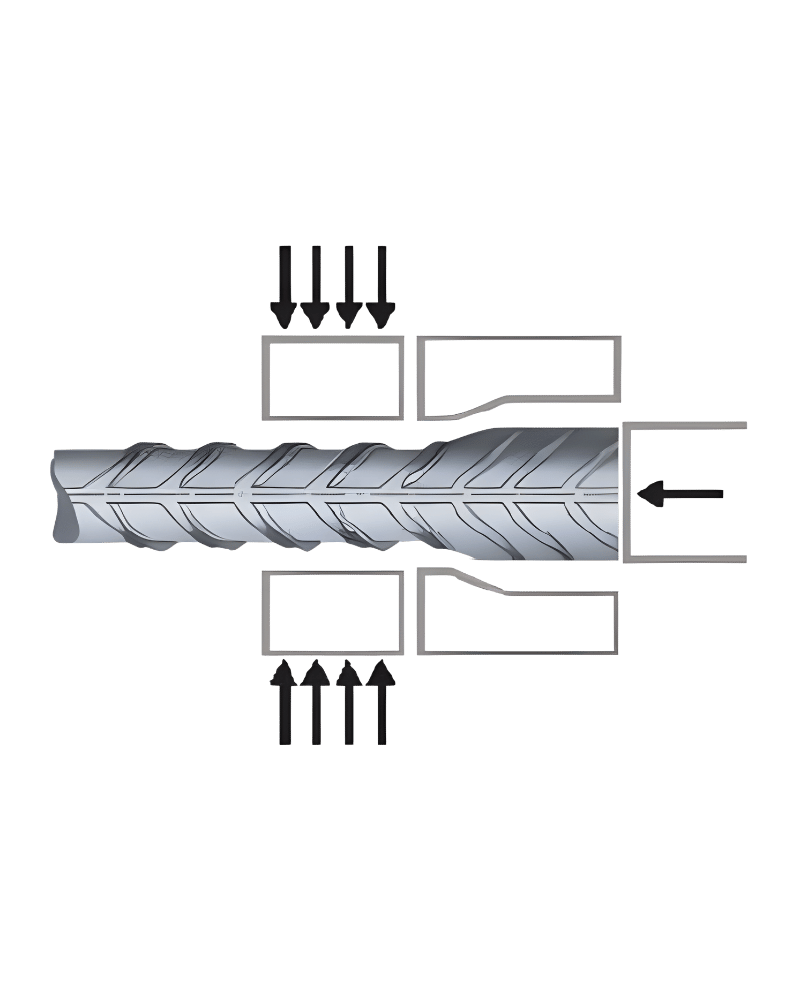

Step B: Cold Upsetting to Enlarge Diameter

Cold‑forging machine enlarging the rebar diameter. Description: The rebar end is cold‑forged to increase its diameter, providing sufficient material to form strong parallel threads.

Step C: Parallel Thread Cutting

Thread‑cutting machine forming parallel threads. Description: Precision cutting forms smooth and accurate parallel threads that ensure seamless engagement with the coupler.

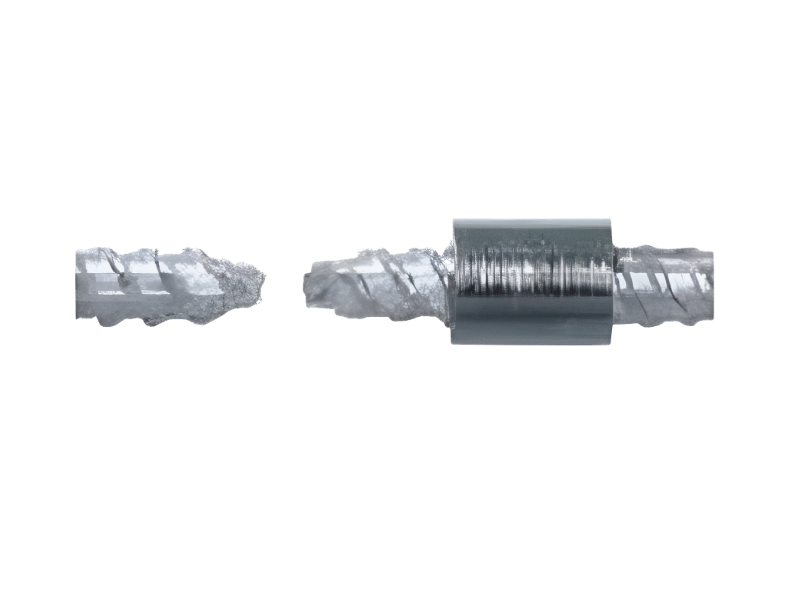

Step D: Rebar Connection and Bar-Break Assurance

Two threaded rebar ends being connected using the coupler. Description: The threaded bars are screwed into the coupler until tight, guaranteeing a bar‑break performance during tensile loading.

Versatile Coupler Applications

Exploring Coupler Uses in Construction

Our couplers are designed for a variety of construction applications, each tailored to specific structural needs. Standard connections facilitate straightforward reinforcement continuity. Position splicing is perfect for scenarios where bar rotation is restricted, while transition splicing connects rebars of differing diameters. These applications ensure structural integrity and adaptability in complex construction environments.

Coupler Applications

The Best Notch rebar coupler system supports various splicing techniques and can be used across multiple structural elements.

Splicing Methods

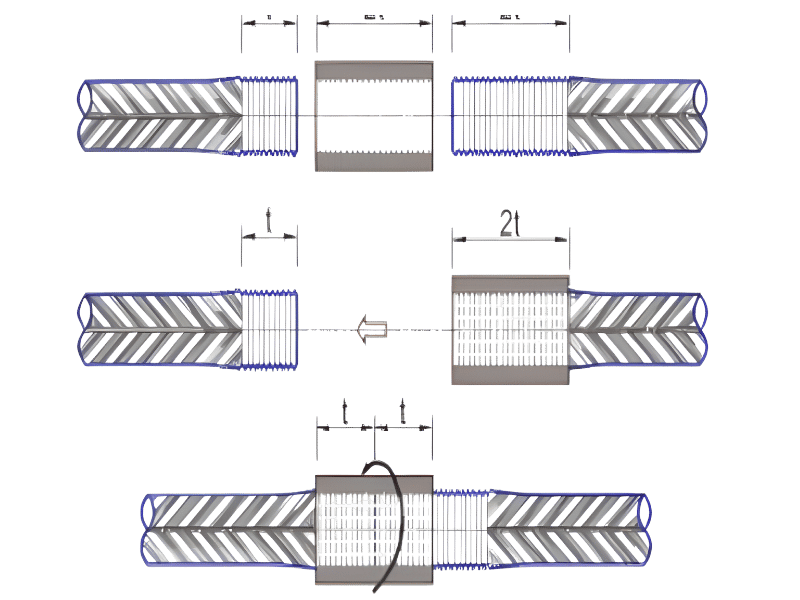

Standard Connection

Illustration of standard lap‑free rebar connection. Description: A typical straight connection where two rebars are aligned and joined using a standard coupler.

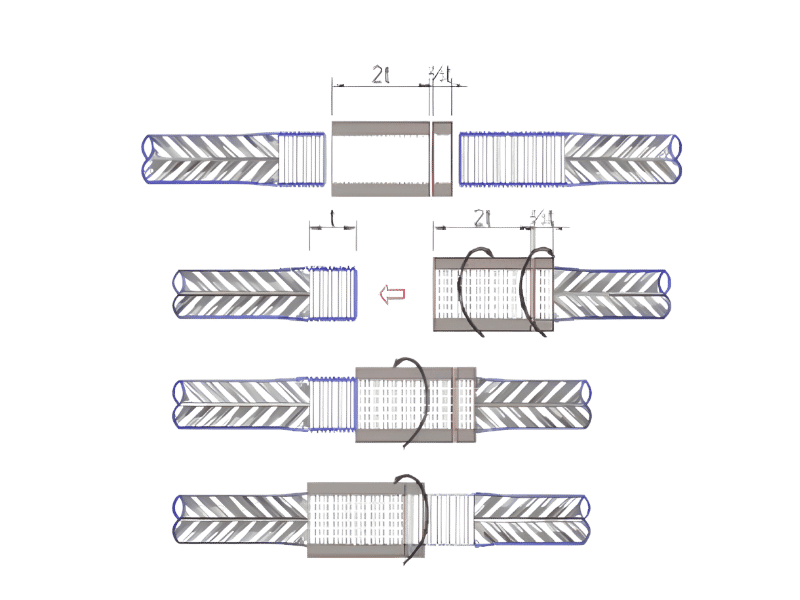

Position Splicing 1

Position splice method for cases with limited bar rotation. Description: Used when one rebar cannot be rotated; position couplers allow installation without full bar movement.

Position Splicing 2

Second type of positional splice used in congested reinforcement zones. Description: Enables secure connection where both bars are restrained or require precise alignment.

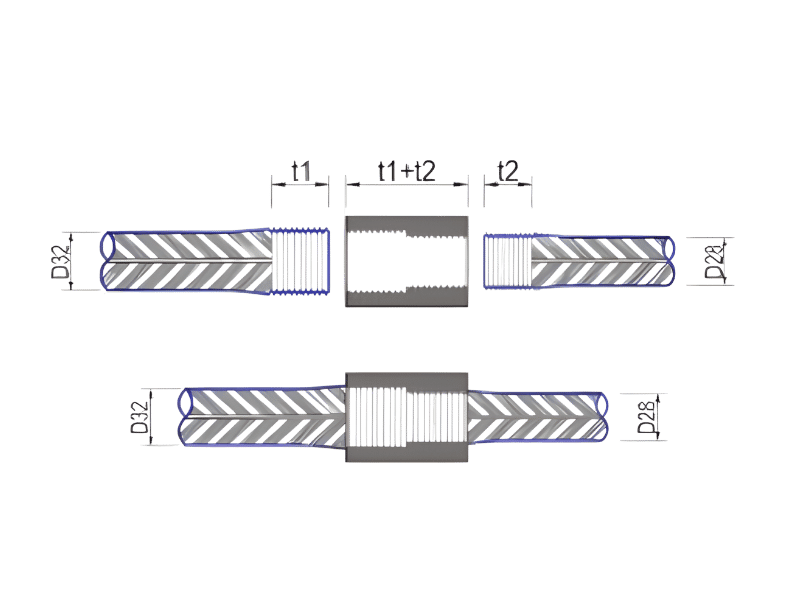

Transition Splicing

Connection between two different-size rebars using a transition coupler. Description: Used when rebar diameters differ and a smooth load transfer is required.

Typical Structural Applications

Best Notch couplers are widely used across major reinforced concrete components.

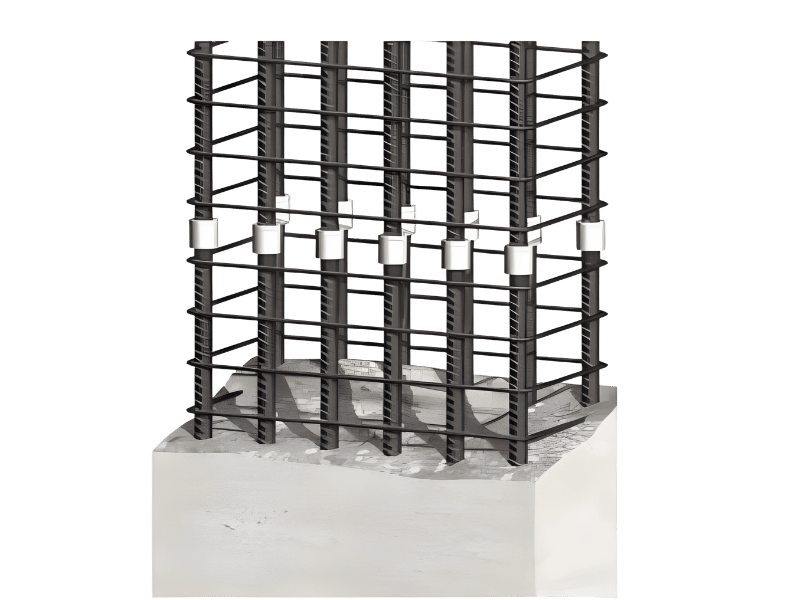

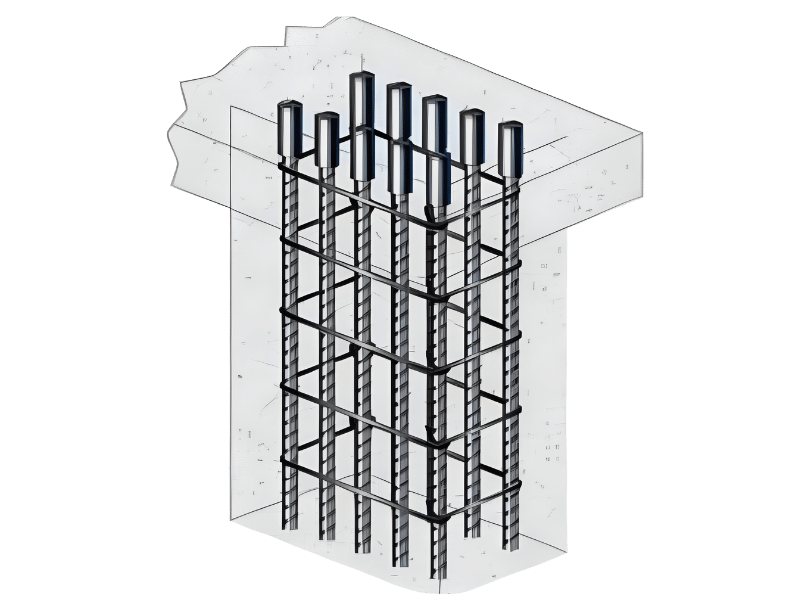

Column Reinforcement

Vertical reinforcement splices in columns. Description: Ensures continuity of vertical reinforcement, reducing congestion and improving structural integrity.

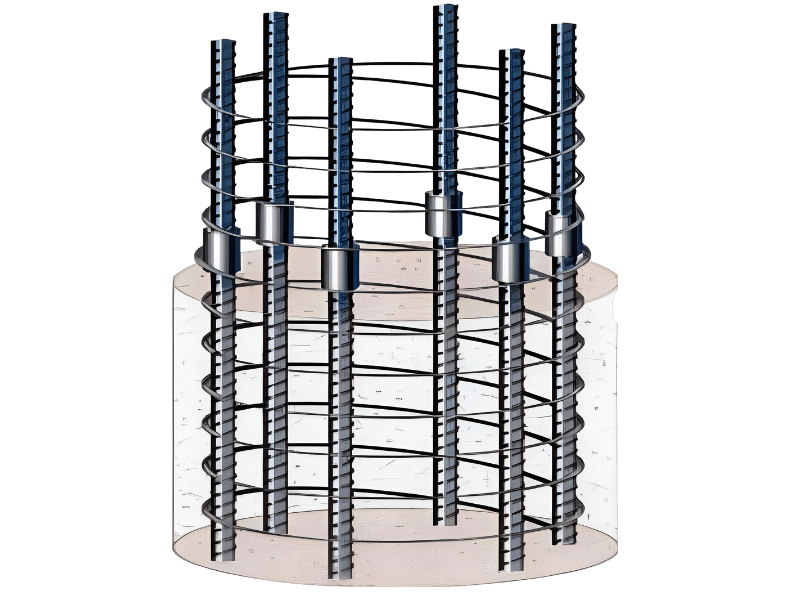

Bored Piles

Coupler connections inside deep foundation piles. Description: Provides high‑strength continuity in pile reinforcement cages.

Waiting Rebar

Pre‑installed rebar with exposed threaded ends. Description: Used for staged construction where future concrete pours require extensions.

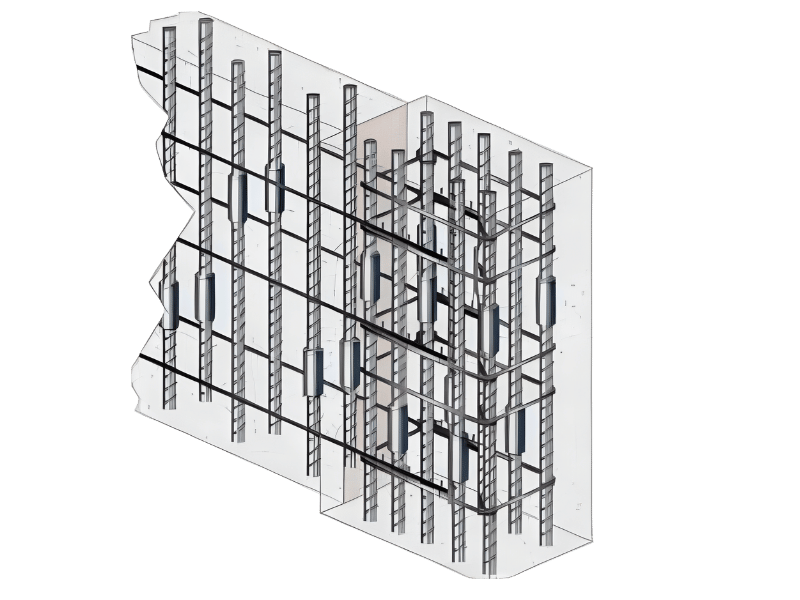

Wall & Shell Structures

Reinforcement splicing within wall and shell elements. Description: Ideal for thin structural members where conventional lap splicing is impractical.

Get in Touch with Best Notch Group LLC

Discover the unparalleled benefits of our rebar parallel thread couplers and how they can enhance your construction projects. At Best Notch Group LLC, we are dedicated to providing top-tier solutions that reinforce trust and excellence in every build. Contact us today to learn more about our innovative products and how they can meet your specific construction needs.

BEST NOTCH GROUP LLC.

Best Notch Group LLC, headquartered in Dubai, is a leading rebar coupler supplier in the UAE, specializing in high-quality and advanced connection systems for the construction industry. We manufacture and supply a wide range of couplers.