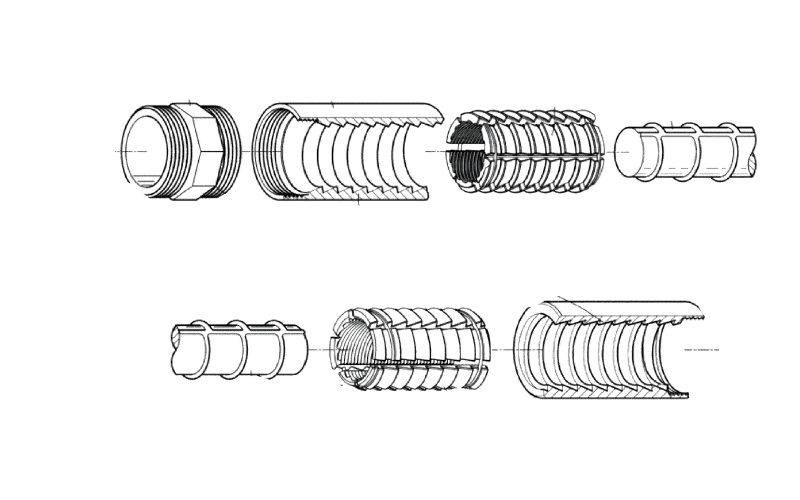

One-Touch Coupler

“Engineered for Reliability, Built for Durability.”

One-Touch Coupler

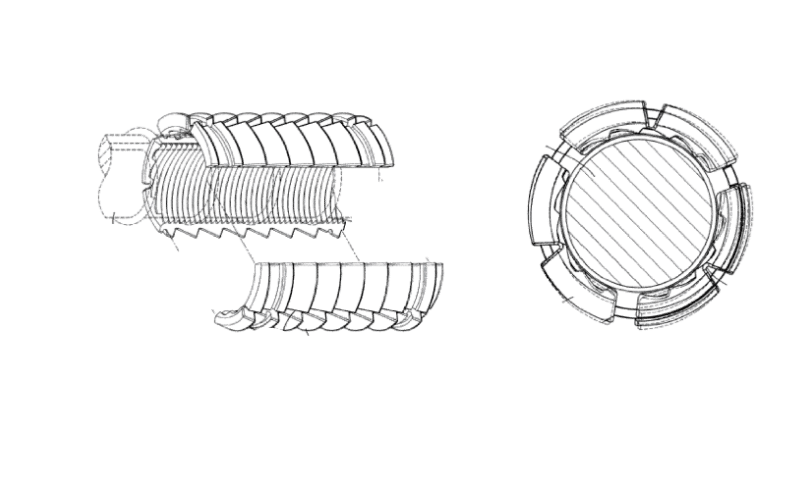

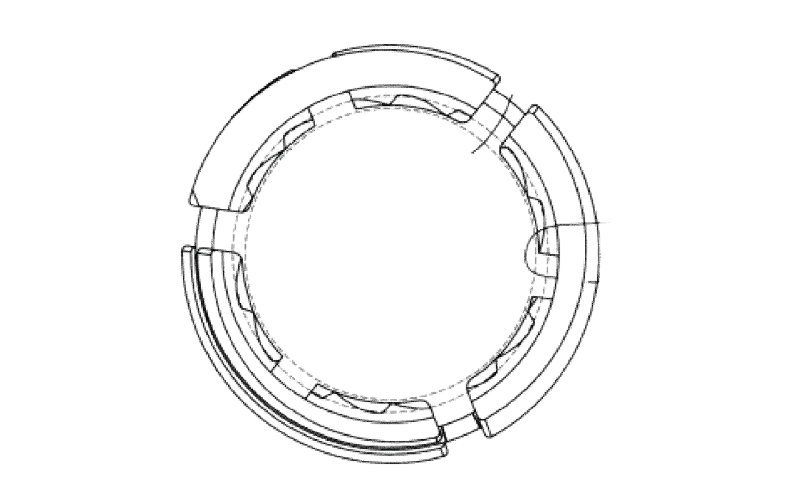

The Weldable Coupler is a specialized rebar splicing solution designed to provide a secure, permanent connection between reinforcement bars and structural steel components. One end of the coupler is threaded to connect with a rebar, while the other end features a weldable plate or plain end that can be directly welded onto steel structures.

This makes it ideal for integrating reinforced concrete with steel frameworks in applications such as composite structures, columns, shear walls, and precast elements. With robust performance under static and dynamic loads, the Best Notch Weldable Coupler ensures seamless continuity between concrete reinforcement and steel elements.

Key Features

- Dual Function – One end connects to rebar, the other welds onto steel.

- High Structural Strength – Provides full load transfer between rebar and steel.

- Seamless Integration – Bridges concrete and steel in hybrid structures.

- Durable Design – Withstands seismic loads, fatigue, and heavy dynamic stresses.

- Customizable Ends – Available with plain, beveled, or plate-end weld surfaces.

- Code Compliance – Manufactured to meet international building and welding standards.

Technical Specifications

|

Parameter |

Details |

|

Coupler Material |

High-grade carbon steel / alloy steel |

|

Rebar Compatibility |

Fe500 / Fe550 / ASTM A615 / BS4449 |

|

Bar Diameter Range |

12 mm – 50 mm (custom sizes available) |

|

Weld End Options |

Plain end / Beveled end / Weld plate |

|

Thread Type |

Parallel ISO Metric threads |

|

Tensile Strength |

≥ 100% of parent bar strength |

|

Welding Compatibility |

MIG, TIG, Arc, or Gas welding methods |

|

Corrosion Protection |

Black finish, galvanization, or epoxy coating |

|

Compliance |

ISO 15835, ACI 318, BS8110, AWS D1.1 |

Applications

- Composite concrete-steel structures

- Precast construction with steel connections

- Bridges and tunnels with embedded steelwork

- Pile foundations with steel plates or jackets

- Structural retrofitting and strengthening works

- Seismic reinforcement in hybrid structures

Advantages

- Provides direct bar-to-steel connection, eliminating lap splices or anchors.

- Suitable for congested reinforcement areas where lapping is impractical.

- Enhances design flexibility for engineers in composite structures.

- Ensures reliable performance in dynamic load conditions (bridges, seismic zones).

- Reduces site congestion and installation time.

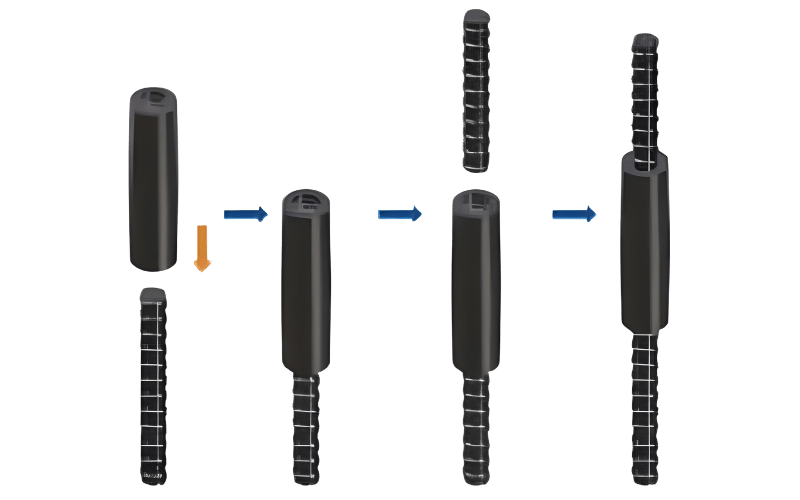

Installation Process

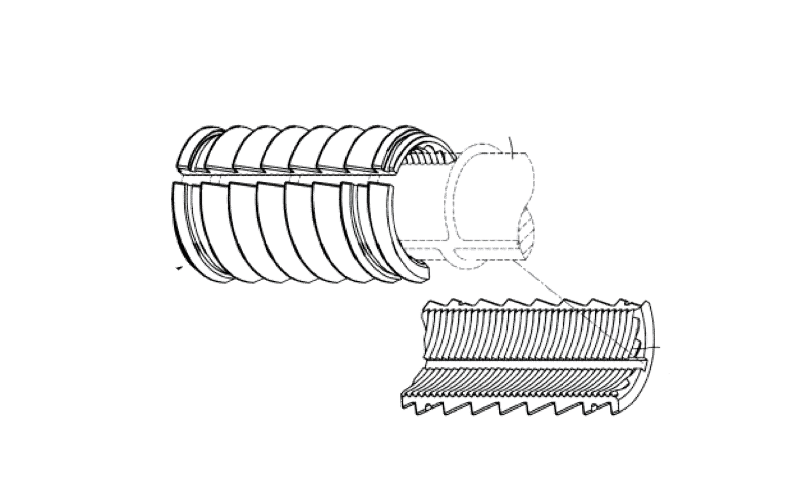

Step 1: Rebar Connection

- Cold-forge and thread the rebar end.

- Screw the threaded bar into the coupler until it reaches the internal stop.

Step 2: Positioning for Welding

- Place the coupler’s weldable end against the steel surface (plate, beam, or column).

- Ensure alignment is correct according to the structural drawings.

Step 3: Welding

- Weld the coupler end to the steel surface using an approved welding method (Arc/MIG/TIG).

- Ensure continuous weld around the coupler end for maximum strength.

Step 4: Quality Check

- Perform visual inspection and, if required, non-destructive weld testing (NDT).

- Confirm rebar-coupler and coupler-steel integration is secure.

Variants Available

- Plain-End Weldable Coupler – For direct welding to steel plates.

- Beveled-End Weldable Coupler – For stronger weld penetration.

- Plate-End Weldable Coupler – Comes with a pre-attached steel plate for easy anchorage.

Quality & Testing

Every batch of Weldable Couplers is tested for:

- Tensile and slip resistance

- Weld strength and penetration depth

- Fatigue resistance for seismic applications

- Dimensional accuracy

- Corrosion resistance of finishes/coatings

OUR PRODUCTS

Parallel Threaded Couplers

Pressed Coupler

Weldable Coupler

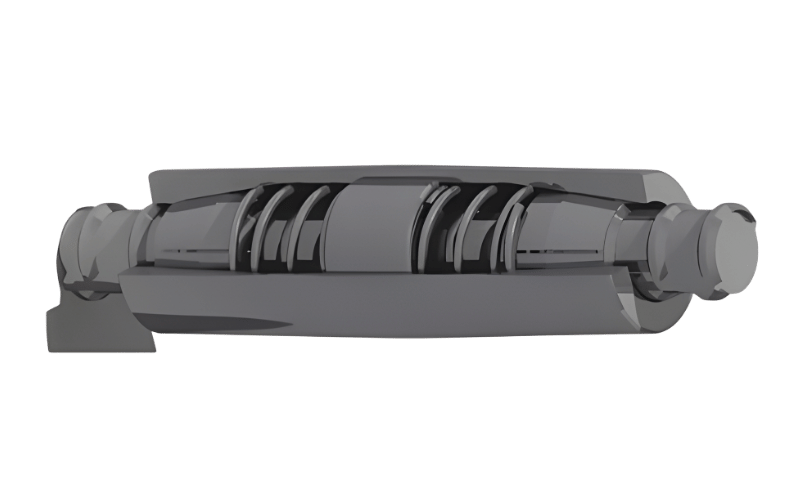

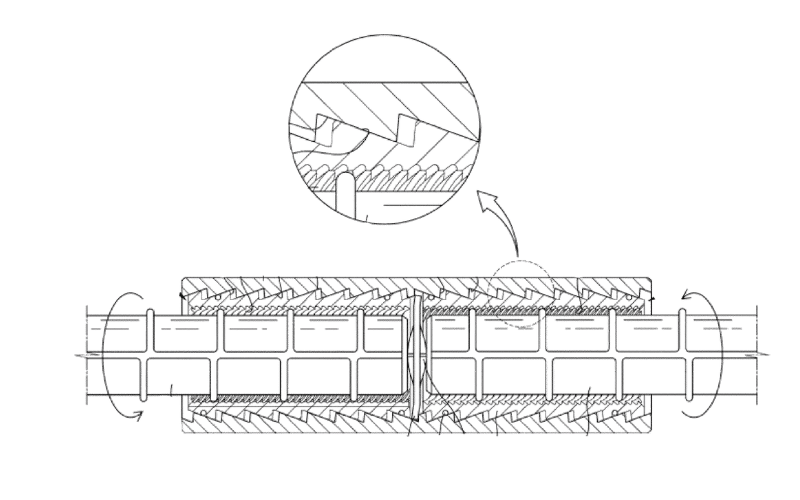

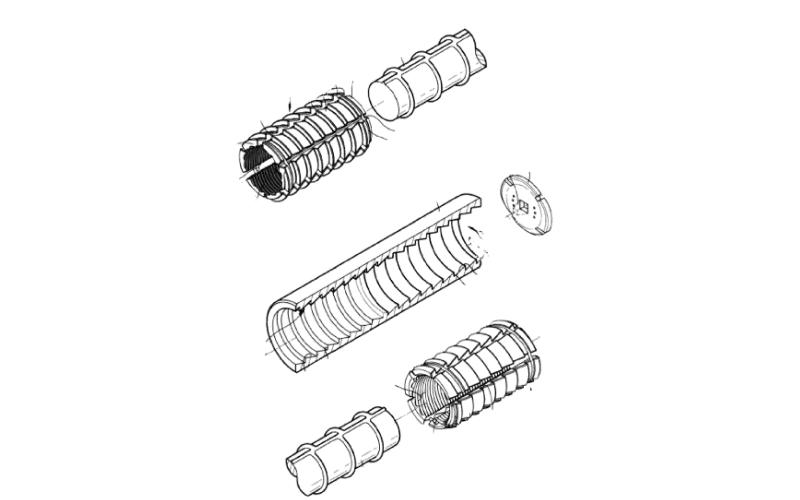

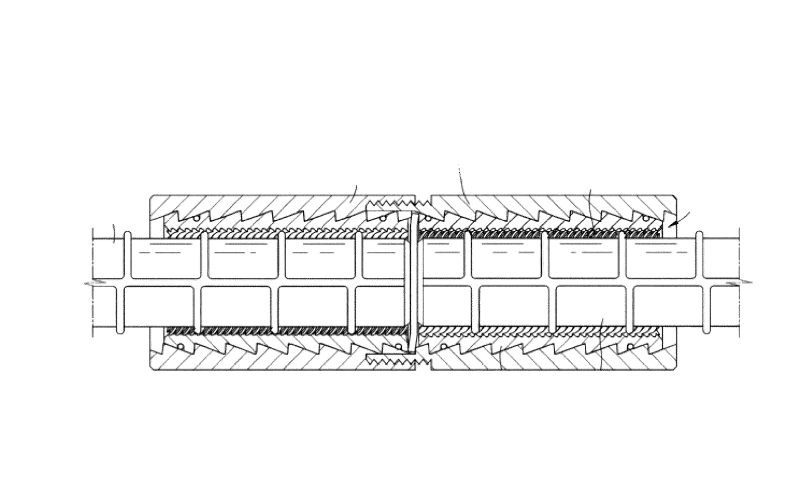

One-Touch Coupler

BEST NOTCH GROUP LLC.

Best Notch Group LLC, headquartered in Dubai, is a leading rebar coupler supplier in the UAE, specializing in high-quality and advanced connection systems for the construction industry. We manufacture and supply a wide range of couplers.